Your cart is currently empty!

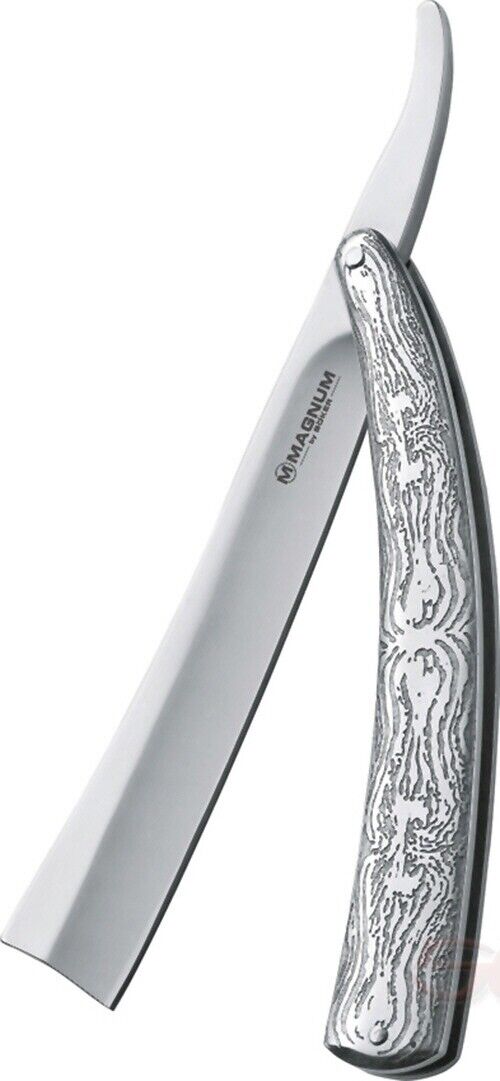

Boker Shaving Straight Razor Knife Sweeny Todd's Thick Blade Etched Handle

$28.97

1 in stock

Description

|

Boker Shaving Straight Razor Knife Sweeny Todd’s Thick Blade Etched Handle

|

|

|

Boker

Sweeny Todd’s

THICK

Shaving Straight Razor Knife

#01LG242

(Contains NO Ivory)

Condition: New

Legal Disclaimer: By bidding on or purchasing this item, you certify that you are over the age of 18 and are in compliance with your state and local laws regarding this item. Survivors Edge, LLC will not be responsible for the illegal purchase or use of the product.

Handle: Etched thick and heavy stainless steel handle

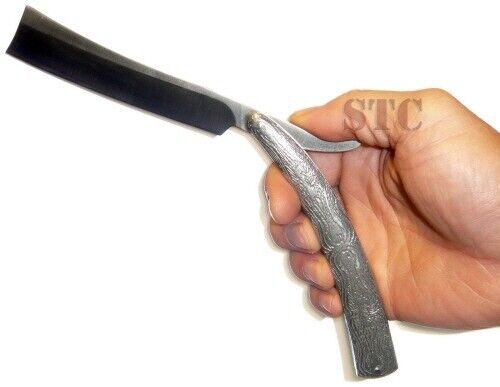

Blade: 4 5/8″ 440 Stainless steel with a THICK 3/16″ SPINE! (See photo)

Size: 7 3/8″ closed, 10 9/16″ overall open

Warranty: For life with manufacturer “Every Boker product is guaranteed to be free from defects in material and workmanship for the life of the product to the original owner. If this item should fail under normal use, we will repair it or replace it at no charge with an item of equal or better value.”

Make no mistake! This is the THICKEST blade we have EVER seen on a razor knife! 5mm or 3/16″ THICK!

Materials: In general, the blades of straight razors are made of steel; the more recent razors have blades made from stainless steel. Often found engraved or etched on the blades are markings identifying the manufacturer and/or the model of the razor.

Handles are made from a wide variety of materials, including celluloid (an early plastic), wood, rubber, horn, ivory, Bakelite,vegetable ivory, and metal. Inlays and additions can be of mother of pearl, silver, copper, ivory, wood, tortoiseshell — the list is almost endless. While some materials, such as metal, are easy to identify, others (such as ivory and celluloid) are virtually indistinguishable without resorting to chemical tests. Thus,instead of addressing a series of different materials, the following care and handling suggestions for straight razors are meant to be generally applicable.

Care:

In general, the best environment in which to store straight razor sis well-ventilated, dark, room temperature (72F or 20C), and neither too dry, nor too damp. Your underwear drawer likely meets these requirements; it is best to keep the razors near the front of the drawer, however, so that the air around them is circulated (air circulation is particularly important if the handle of your straight razor is celluloid, as unventilated celluloid can quickly deteriorate). Razors should not be stored in an area that gets very hot, such as an attic, as celluloid is very flammable, and has been known to spontaneously combust at temperatures as low as 50C(125F).

It is advisable to keep straight razors out of water and away from liquids as much as possible — both because water will encourage the iron-based blades to rust, and also because water can cause serious damage to manhandle materials. Cleaning razors with bleach, ammonia or detergents is discouraged, as these substances can also cause damage.

Blades:

Metal polishes, such as Brasso, Silvo, or Autosol should never be used on the blade of a straight razor. As well as damaging the surface, they can leave polish residues which are both unattractive, and can be harmful to the blade and handle.

If the blade is exceptionally dull or nicked, the use of a sharpening stone is recommended. A leather razor strop can be used to maintain a keen edge. You know you’re getting close when you can slice a piece of paper with your razor.

It is not uncommon to find rust on the blades of straight razors,particularly the earlier blades, made before the invention of stainless steel. The rust can be removed using either a soft 3M scrub pad (the white ones), or 0000 (extremely fine) steel wool. Be careful not to scratch the handle!

Next, clean the entire surface of the blade with a Q-tip dampened with either ethyl alcohol or rubbing alcohol. This will help degrease the blade. Then, apply a thin coat of light mineral oil to the blade; let it sit for a short while (10 minutes, or so), and then wipe the excess oil off using a clean, dry cloth. This oil coating will help prevent any further rusting.

If you use your straight razor, use rubbing alcohol to remove the oil before use, and again after use to clean the blade. Use mineral oil to re-oil the blade after use, as well as after sharpening. Be careful not to get any alcohol or oil on the handle.

Handles:

Coatings such as lacquers, waxes, oils, and polishes should be avoided, as they can do more harm than good (trapping dirt, or trapping chemicals that greatly increase rates of deterioration).

Likewise, soaps and detergents should also be avoided when cleaning handles. For general cleaning, use distilled water. Do not immerse or soak the handle in the water; rather, wipe the handle with a damp cloth, and dry immediately using another clean, absorbent cloth. To cut any grease present, use a mixture of distilled water and household ammonia (1 or 2 drops of ammonia in 2 cups of water); rinse quickly with a damp cloth,and dry.

To clean wooden handles, carefully “erase” the dirt using a soft,white vinyl eraser. The eraser bits can be brushed away using a soft bristle brush. Wood handles should not be washed with water.

If you have a broken razor, it is best not to fix it yourself — certain adhesives may cause damage to the materials. As well, certain repairs may cause a loss in value greater than the damage alone. Consult a conservator familiar with the materials involved.

Keep an eye on your razor collection, and watch for any signs of deterioration — color change, odors, cracking, flaking, warping,bubbling, etc. Deteriorating razors should be isolated and stored away from the rest of your collection, to prevent further damage(for example, deteriorating celluloid will cause other, “healthy”celluloid (as well as other materials such as leather), to also begin deteriorating).

In general, the basic care outlined above will go a long way to keeping your razor in good shape for many years. For more in-depth concerns (i.e. a cloudy tortoiseshell handle, adhesive residues, broken handles), consult with a conservator who is familiar with the material in question.

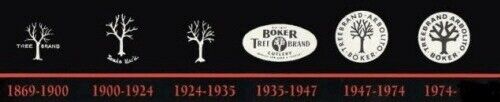

The history of Boker from the Heinr. Boeker Company:

A giant chestnut tree, shading the small Boeker tool factory in Remscheid in the 17th century, is the oldest traceable symbol connected with the Boeker name. Apparently, Boeker tools were very successful, since they were among the leading products in Germany and neighboring countries 100 years later.

Due to the increasing demand in a restless political era, Hermann and Robert Boeker decided in 1829 to begin with the production of sabers. As early as September 1830, the accounting records indicate a weekly production of 2,000 items, made by 64 smiths, 47 grinders and a large number of unskilled laborers. In view of the constantly increasing variety of tools and cutting instruments and the good opportunities for worldwide sales, the family realized that the individual steps in the manufacturing process had to be spread out for optimal realization of its interests. As a result, Hermann Boeker emigrated and founded H. Boeker & Co. in New York. Young Robert developed his enterprise in Canada, founding a branch in Mexico later in 1865. This branch is still a market leader in its country under the name of Casa Boeker.

Heinrich crossed the nearby Wupper river and went to Solingen, where the German industry of cutting tools was growing by leaps and bounds at that time. In 1869, he founded Heinr. Boeker & Co. with Hermann Heuser, a well-known specialist in the field of cutting tools. The Boeker family in Remscheid and their overseas cousins had a lot of interest in and a great demand for shaving blades, scissors and pocket knives from Heinrich’s new enterprise. They had to identify their products for the overseas markets in a simple way, since many customers and consumers had problems with the German name Boeker ? not considering the fact that illiteracy was widely spread. In Heinrich’s opinion, the chestnut tree near the Remscheid facility represented an ideal, easy-to-remember symbol. This brand symbol was owned by the Remscheid company, together with a second logo, the arrow. One of the few valuable documents that survived the total destruction of WWII is an ad by Boeker, Remscheid, from the year 1874, showing both logos.

The relationship between the two Boeker companies had always been extremely friendly. Therefore, Heinrich was allowed to take the tree symbol across the river with him ? without any big fight or cost. Since then, not a single Boeker article has left the Solingen factory without being identified by the tree symbol. After more than 100 years of existence the old chestnut tree was the victim of lightening. In 1925 a talented artist carved a copy of the majestic tree on a piece of the trunk. This original piece of art decorates the boss’ office in the Boeker plant.

As early as 1900, the majority of articles produced by Boeker were distributed in the US market. H. Boker & Co. in New York concentrated primarily on cutting tools from Solingen. Soon pocket knives became more important than scissors, shaving blades and eating utensils. The demand increased even more rapidly than Solingen was able to supply, so that the Americans in New York began their own production of pocket knives. A little later, pliers were included as well. Since the tree symbol had become well known by then and the various branches of the international Boeker family enjoyed an excellent relationship among each other, it was not difficult to receive permission from the Solingen relatives to use the tree symbol also for the American products. Since that time, two different lines of Boeker knives have been on the American market with the same brand symbol, sometimes even with the same article numbers, but one line was made in the USA and the other in Solingen. Only the declaration of marketability clarified that one line was from Boker USA and the other from H. Boker Improved Cutlery Solingen. The relationship was interrupted during WWII. The Solingen factory burned down completely. None of the equipment, tools, catalog materials or samples was spared. Those few originals from the past we have today survived the war in private homes and were made available to the company. The firm lost one of its most valuable assets: the registration of the tree symbol for the American market was confiscated pursuant to American law. John Boker Jr. acquired it in New York, in order to secure it for the distribution of the American and German products. Soon after the war, the destroyed factory was rebuilt. Those loyal skilled workers who had survived the war, returned and helped with the reconstruction of the building as well as the production, gradually regaining the previous high standard of quality.

The American cousins renewed their business contact with Solingen and started to place orders. Within a few years Boker, New York, had again become the principal customer. Models like the 7588 and 7474 and the most expensive item, the sports knife “Flagship Model 182” could not cross the ocean fast enough to reach Bfriends all over the country.

In the early 60s, Boker USA was sold and eventually acquired by the well-known scissors manufacturer Wiss & Sons. Wiss retained the manufacture of Boeker knives and sold them together with Solingen products. Of course, this meant that the Boeker scissors ceased to be competitors of the Wiss line in the American market. In the early 70s, Wiss sold to Cooper Industries, a multinational company. This new change in America proved to be advantageous for Boker.

A very close business, as well as personal relationship developed with this industrial giant. Due to its strength on the market, Cooper was able to restore the original magnitude of the Boeker name. Thanks to the very lively business activities with Cooper for eight years, the Solingen facility could streamline its production and develop new, modern products. Without exaggeration, Boker manufactures the largest assortment of high-quality knives for sportsmen and collectors with an unsurpassed variety of materials for blades and handles. Today, Boeker knives range from 320-layer Damascus steel to very modern ceramics, with handles ranging from high-quality mother-of-pearl to Thuya root wood and state-of-the-art synthetics…

In 1983 Cooper discontinued its own knife production. Models still in demand are being manufactured in Solingen today. As a result of friendly negotiations, Cooper restored the American trademark rights three years later, providing Solingen with the opportunity to become self-reliant in the huge American market. Thus, in 1986, Boker USA, Inc. was created in Denver, Colorado. Chuck Hoffman, the man who was involved with the company then, is still active as CEO today, working with a young, energetic team.

The great importance of Boeker in the South American markets (Argentina and Chile) and in Mexico is due to the efficient men of the Boeker family, who were active for us in these countries in the 19th and 20th centuries. Today’s trademark includes the terms TREEBRAND and ARBOLITO. Since the Argentinean market in particular is subject to extreme economic and political fluctuations, the good name ARBOLITO was in danger of being forgotten. In 1983, Boeker Arbolito S. A. was founded jointly with the Salzmann family primarily to manufacture household and work knives in Argentina. Thanks to the constant modernization and expansion of product lines the company in Buenos Aires is able to compete worldwide with selected products today.

Shop us at SurvivorsEdge and PatchesAndStickers. SurvivorsEdge is a Service-Disabled Veteran-Owned Small Business (SDVOSB) specializing in United States Marine Corps gear, survival gear, karambit and zytel polymer knives, Arkansas sharpening stones, and cigar and tobacco pipes and accessories. Visit us on these sites for specials and coupons! Are you a Veteran in crisis or concerned about one? You’re not alone—the Veterans Crisis Line is here for you. You don’t have to be enrolled in VA benefits or health care to call. |

|

|

|

Additional information

| Brand | |

|---|---|

| Item Condition | |

| Material | |

| Product Type |